歡迎進入山東恒能環保能源設備有限公司

歡迎進入山東恒能環保能源設備有限公司

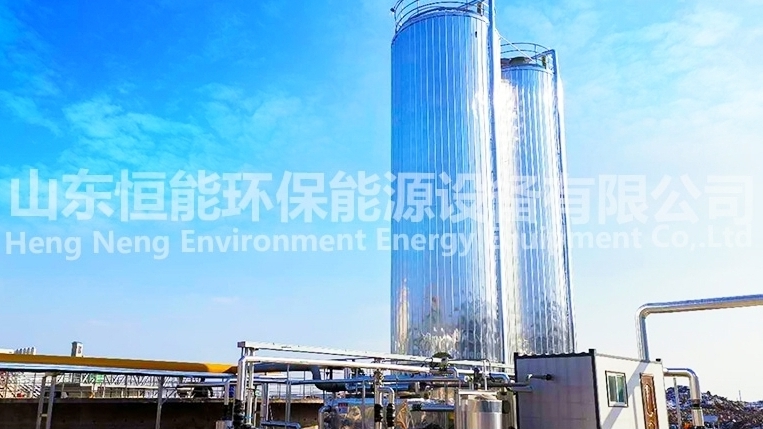

沼氣工程流程沼氣脫硫塔:沼氣作為一種能源,在使用前必須經過凈化,使沼氣的質量達到標準要求。《氣工程技術規范》NY/T1220.2-2006規定,沼氣低熱值>18MJ/m3,沼氣中H2S質量濃度<20mg/m3,沼氣溫度<35。沼氣凈化主要包括脫硫、脫水和過濾。脫硫:沼氣作為能源利用時,要求H2S的質量濃度符合有關要求,否則對管道、設備(如鍋爐、沼氣發動機等)有腐蝕作用。脫硫方法有干法脫硫、濕法脫硫、水噴淋脫硫等。脫水:水分與沼氣中的H2S反應產生氫硫酸,腐蝕管道和設備;水分凝聚在檢查閥、安全閥、流量計、調節器等設備的膜片和隔膜上,影響其準確性;水分能增大管道的氣流阻力;水分能降低沼氣的熱值。脫水方法有冷凍法、吸附法、化學反應法等。過濾:沼氣中含有雜質,尤其在消化池運行初期或消化狀態不穩定時雜質較多。因此,進入內燃機前一般應采取過濾措施。濾網可設在沼氣管道上,一些發動機在設備內部也設有濾網,應定期清洗。沼氣脫硫塔脫硫工藝的選擇:干法脫硫干法脫硫中常見的方法為常壓氧化鐵脫硫法。在常溫常壓下沼氣通過脫硫劑床層,沼氣中硫化氫與活性氧化鐵接觸,生成硫化鐵和硫化亞鐵。然后進行再生,含有硫化物的脫硫劑與空氣中的氧接觸,當有水存在時,鐵的硫化物又轉化為氧化鐵和單質硫。這種脫硫、再生過程可進行多次,直至氧化鐵脫硫劑表面的大部分空隙被硫或其他雜質覆蓋而失去活性為止。一旦脫硫劑失去活性,需將脫硫劑從塔內卸出,攤曬在空地上,然后均勻地在脫硫劑上噴灑少量稀氨水,利用空氣中的氧,進行自然再生。氧化鐵的脫硫反應如下:Fe2O.3H2O 3H2S→Fe2S3 6H2OFe2O3.3H2O 3H2S→2FeS S 6H2O氧化鐵的再生反應如下:

Biogas engineering process: Biogas desulfurization tower: Biogas, as an energy source, must be purified before use to ensure that its quality meets the standard requirements. According to the Technical Specification for Gas Engineering NY/T1222.2-2006, the low calorific value of biogas is greater than 18MJ/m3, the mass concentration of H2S in biogas is less than 20mg/m3, and the biogas temperature is less than 35. Biogas purification mainly includes desulfurization, dehydration, and filtration. Desulfurization: When biogas is used as an energy source, it is required that the mass concentration of H2S meets relevant requirements, otherwise it will have a corrosive effect on pipelines and equipment (such as boilers, biogas engines, etc.). The desulfurization methods include dry desulfurization, wet desulfurization, water spray desulfurization, etc. Dehydration: The reaction between water and H2S in biogas produces hydrogen sulfate, which corrodes pipelines and equipment; Moisture condenses on the membranes and diaphragms of inspection valves, safety valves, flow meters, regulators, and other equipment, affecting their accuracy; Moisture can increase the airflow resistance of pipelines; Moisture can reduce the calorific value of biogas. Dehydration methods include freezing, adsorption, chemical reaction, etc. Filtration: Biogas contains impurities, especially in the early stages of digestion or when the digestion state is unstable. Therefore, filtering measures should generally be taken before entering the internal combustion engine. The filter can be installed on the biogas pipeline, and some engines also have filters inside the equipment, which should be cleaned regularly. Selection of desulfurization process for biogas desulfurization tower: The common method in dry desulfurization is atmospheric pressure iron oxide desulfurization. At room temperature and pressure, biogas passes through a desulfurizer bed, and hydrogen sulfide in the biogas comes into contact with active iron oxide to produce iron sulfide and ferrous sulfide. Then regeneration is carried out, and the desulfurizer containing sulfides comes into contact with oxygen in the air. When water is present, iron sulfides are converted into iron oxide and elemental sulfur. This desulfurization and regeneration process can be carried out multiple times until most of the voids on the surface of the iron oxide desulfurizer are covered by sulfur or other impurities and lose their activity. Once the desulfurizer loses its activity, it needs to be unloaded from the tower, spread on the open space, and then evenly sprayed with a small amount of dilute ammonia water on top of the desulfurizer, using oxygen in the air for natural regeneration. The desulfurization reaction of iron oxide is as follows: Fe2O.3H2O 3H2S → Fe2S3 6H2OFe2O3.3H2O 3H2S → 2FeS S 6H2O. The regeneration reaction of iron oxide is as follows:

脫硫劑一次裝入后,平時不需維護,當出口沼氣的硫含量超標時,應更換脫硫劑。更換出來的脫硫劑可以再生,再生的次數與脫硫劑的品質有關,一般可以再生2~3次。濕法脫硫濕法脫硫有直接氧化法、化學吸收法、物理吸收法。目前國內常用的主要是直接氧化法脫硫,將硫化氫在液相中氧化成單質硫,流程比較簡單,可以直接得到單質硫。這種方法主要用于處理硫化氫濃度較低而二氧化碳濃度較高的氣體。這種脫硫方法的缺點是溶液吸收硫化氫的硫容量低,因此溶液循環量大、回收硫的處理量大。適用于脫硫量<10t/d的氣體。濕法脫硫反應如下:

After the desulfurizer is loaded once, it does not need to be maintained normally. When the sulfur content of the exported biogas exceeds the standard, the desulfurizer should be replaced. The replaced desulfurizer can be regenerated, and the number of regenerations depends on the quality of the desulfurizer. Generally, it can be regenerated 2-3 times. Wet desulfurization includes direct oxidation method, chemical absorption method, and physical absorption method. At present, the commonly used method in China is direct oxidation desulfurization, which oxidizes hydrogen sulfide into elemental sulfur in the liquid phase. The process is relatively simple and can directly obtain elemental sulfur. This method is mainly used to process gases with low hydrogen sulfide concentration and high carbon dioxide concentration. The disadvantage of this desulfurization method is that the sulfur capacity of the solution to absorb hydrogen sulfide is low, resulting in a large circulation volume of the solution and a large processing capacity for sulfur recovery. Suitable for gases with desulfurization capacity<10t/d. The wet desulfurization reaction is as follows:

原料氣進入脫硫塔底部,通過塔內填料層時,與塔頂噴淋而下的脫硫液(堿液)逆流接觸,堿液吸收硫化氫生成NaHS,塔頂出來的凈化氣中硫化氫質量濃度下降到20mg/m3,脫硫氣體由塔頂流出,經氣液分離后進入下一工序。吸收了硫化氫的溶液經循環泵送入再生槽進行再生,再生后溶液經液位調節器進入脫硫塔頂部循環使用。干濕結合法脫硫干濕結合法脫硫效率高,管理一體化,綜合運行費用低,保養維護簡單,設備壽命長、運行可靠,脫硫劑價格低廉,可將脫硫脫水置于一體,設備可長期連續進行脫硫、脫水。用pH值來控制一級脫硫效率。采用干法脫硫進行二級脫硫,使脫硫率提高到99.8%。與干法脫硫相比,干濕結合法脫硫運行費用低,但因設備復雜,需要較高的運行維護操作水平。

When the raw gas enters the bottom of the desulfurization tower and passes through the packing layer inside the tower, it comes into countercurrent contact with the desulfurization solution (alkali solution) sprayed from the top of the tower. The alkali solution absorbs hydrogen sulfide to generate NaHS. The mass concentration of hydrogen sulfide in the purified gas coming out of the tower top drops to 20mg/m3. The desulfurization gas flows out of the tower top and enters the next process after gas-liquid separation. The solution that has absorbed hydrogen sulfide is pumped into the regeneration tank through a circulation pump for regeneration. After regeneration, the solution enters the top of the desulfurization tower through a liquid level regulator for circulation. The wet dry combined desulfurization method has high desulfurization efficiency, integrated management, low comprehensive operating costs, simple maintenance, long equipment life, reliable operation, low desulfurizer price, and can integrate desulfurization and dehydration into one. The equipment can perform desulfurization and dehydration continuously for a long time. Use pH value to control the efficiency of primary desulfurization. Using dry desulfurization for secondary desulfurization, the desulfurization rate was increased to 99.8%. Compared with dry desulfurization, wet dry combined desulfurization has lower operating costs, but due to the complexity of the equipment, it requires a higher level of operation and maintenance.

本文由恒能環保能源設備有限公司友情奉獻.更多有關的知識請點擊:http://m.chinaktws.com/真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from Hengneng Environmental Protection Energy Equipment Co., Ltd. For more related knowledge, please click: http://m.chinaktws.com/ Sincere attitude. We provide you with comprehensive services. We will gradually contribute more relevant knowledge to everyone. Please stay tuned